- Categories:

- Low Volume Liquid Dispensing

BioSpot DX

Ultra-low volume dispensing system with innovative dispensing technology for precise dispensing of nanoliter volumes in diagnostic applications.

Most versatile dispensing workstation for precise nanoliter volume delivery in diagnostic applications

High precision, non-contact nanoliter dispensing system for a wide range of liquids (aqueous, buffers &, DMSO & other organic solvents, ethanol, methanol, beads, oils, ...) on any kind of substrate like chips, stripes, cartridges, electrode arrays, slides, plates & many more

Automate your application

Diagnostic chips

Pre-storage of reagents in small cavities of diagnostic chips or microfluidic cartridges.

Biosensors

Apply consistent coating films on sensor surfaces by reproducible nanoliter droplets.

Lateral Flow

Non-contact spot or line printing for the production of multiplex or line-based lateral flow assays.

MS sample preparation

Reproducible deposition of reference standards on tissue or other substrates for qMSI.

Intuitive software

Printing patterns easily defined by simply clicking on selected positions of your substrate. The Live-View mode allows precise selection directly via the screen.

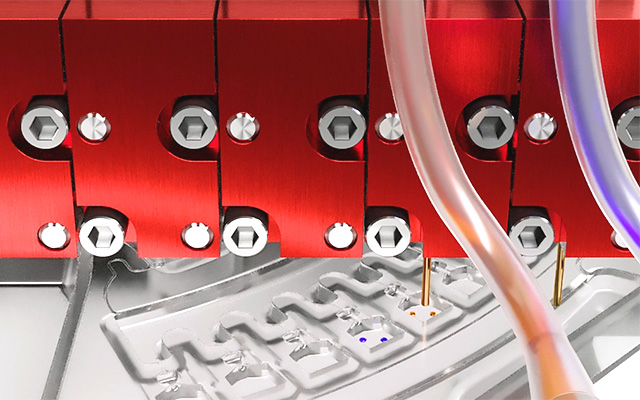

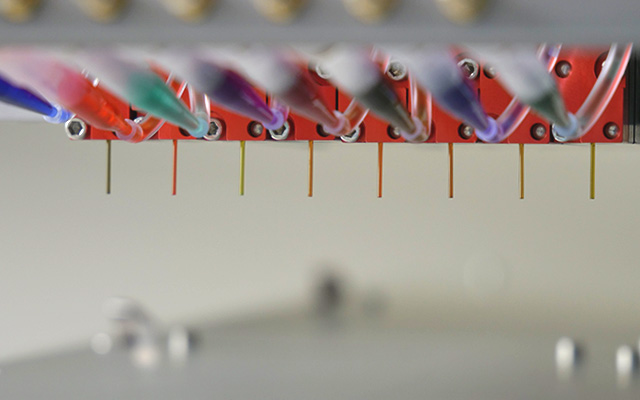

PipeJet® Nanodispenser

Piezo-actuated dispensing technology that generates nanoliter droplets from 2 - 70 nanoliters. Key element is the elastic polymer tip (dispensing pipe) squeezed by the piezo-driven piston to precisely control droplet volume.

Uniform droplet generation

Robust dispensing of nanoliter droplets even for difficult liquid classes.

- From simple to complex print patterns

- Droplet deposition into smallest cavities

- No damage of substrate surface

- Droplet volume control by optical imaging

Non-contact dispense technology

2 nl to 70 nl per droplet

Zero dead volumes

Affordable & easily replacable dispensing tips

High droplet quality - no satellites

Highly reproducible droplet volumes

SmartDrop System

Auto-calibration and performance verification directly on the device by an optical imaging system.

Droplet volume measurement

Droplet analysis directly on the device by optical imaging of single droplets in flight.

SmartDrop System enables the measurement of nanoliter droplet volumes for a non-contact automated droplet volume calibration and verification.

Auto-calibration for all dispense channels

Droplet volume verification

Characterization of new liquid classes

TopView camera

Substrate camera system enables Live-View of the substrate for dispense channel and process control.

Vision guided dispenser control

Bird view of camera enables an easy control of dispense channels as well as quality control (e. g. successfully dispensed droplets).

- Offset correction: Alignment of droplet at target position.

- Dispense on target: Dispense on substrate by a simple point-and-click.

- Quality control: Automated acquisition and storage of image of dispensed droplet/ area.